Chemical composition of the lead-free brass

By A Mystery Man Writer

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

Lead Free Brass Rod, C69300 Eco Brass Rod, IS 4413, BS 2874

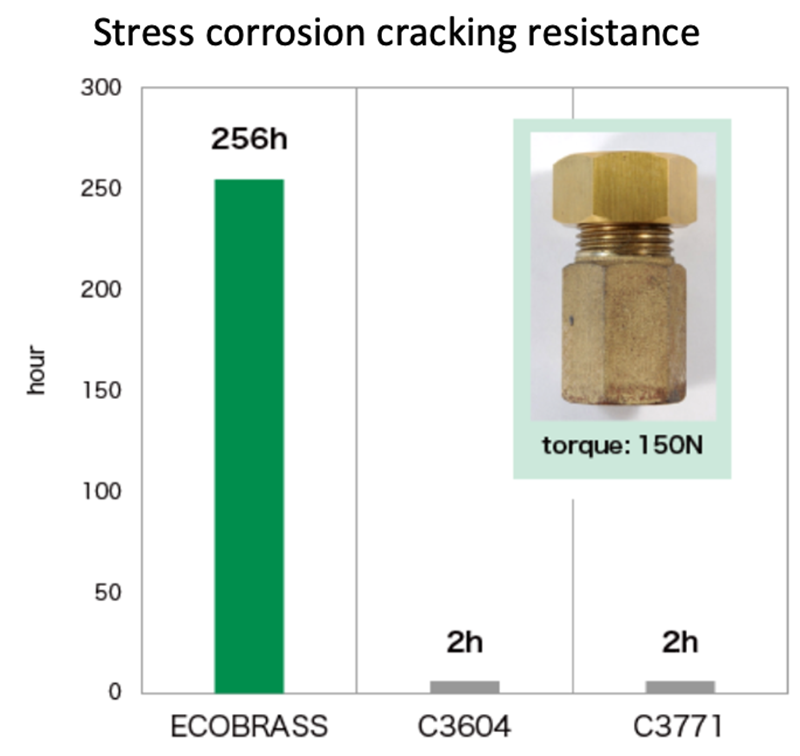

GloBrass,ECO BRASS(Lead-free brass with excellent machinability

Mikko HOKKA, University Lecturer, PhD In Materials Science, Tampere University, Tampere, UTA, Department of Materials Science

dzr brass, eco brass, rods, tubes, hollow, section, manufacturer

Machinability characteristics of lead free-silicon brass alloys as

Energy vs time history of the finite element model for E s 1⁄4 5.0 GPa.

Senor Lead Free Brass

All About Brass as a Manufacturing Material

PDF) Investigation of the effect of different cutting parameters on chip formation of low-lead brass with experiments and simulations

Contours of average Von Mises stress.

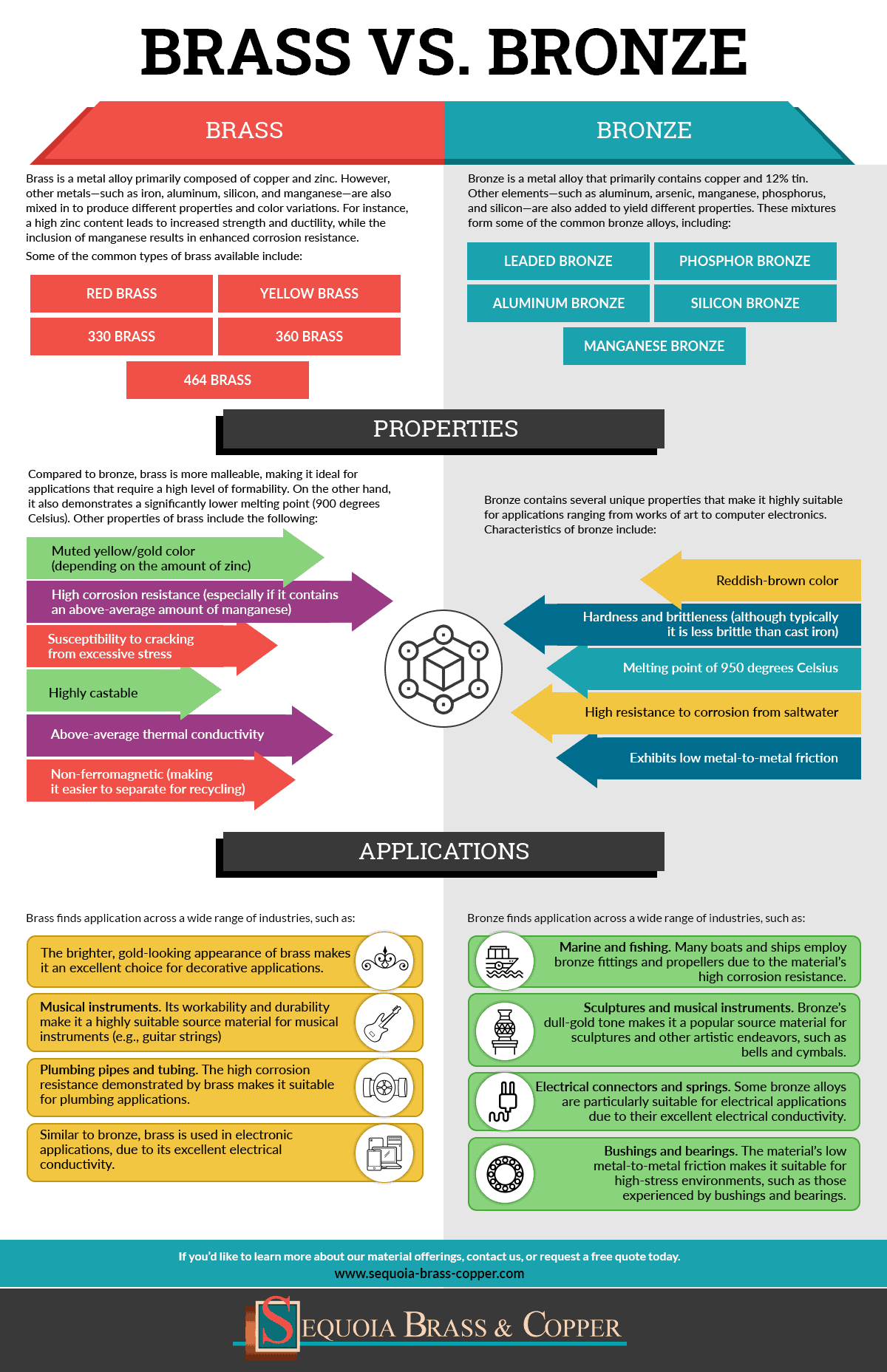

- Metal Comparisons: Brass vs Bronze - Sequoia Brass and Copper

- PDF] Dezincification and Brass Lead Leaching in Premise Plumbing Systems: Effects of Alloy, Physical Conditions and Water Chemistry

- China Copper Alloy Material Code and Composition Chart, China brass valve manufacturer, Brass Fittings Producers -NAFCO

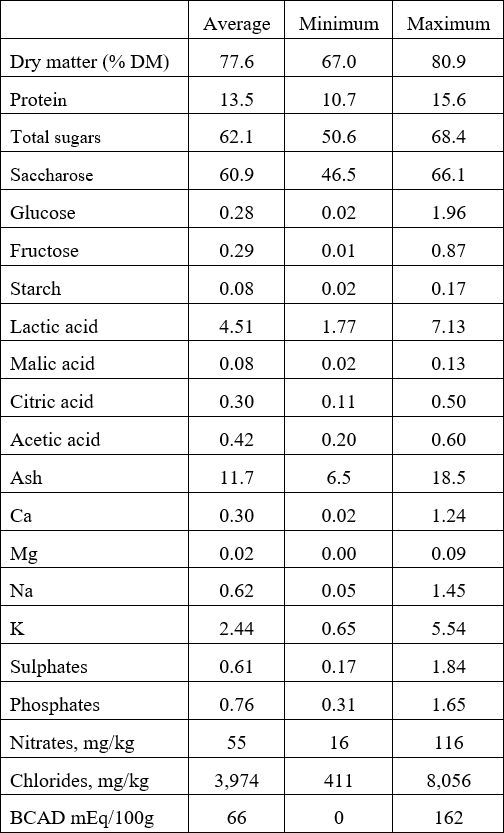

- Differences in the nutritional composition of sugar cane and beet molasses

- How to use phase diagrams and the lever rule to understand metal alloys

- Shady Lady Hair Clip Print Short Pajamas In Cameo Tennis Balls

- Truekind® Everyday Comfort Straps Wireless Shaping Bra

- Faux Patent Leather Leggings - Black – Sanne Alexandra

- Women High Waist Ice Silk Seamless Panties Tummy Control Underwear Briefs

- Bras for small sizes The 3 smallest UK cup sizes – Bra Size Calculator