O-rings norelem FR

By A Mystery Man Writer

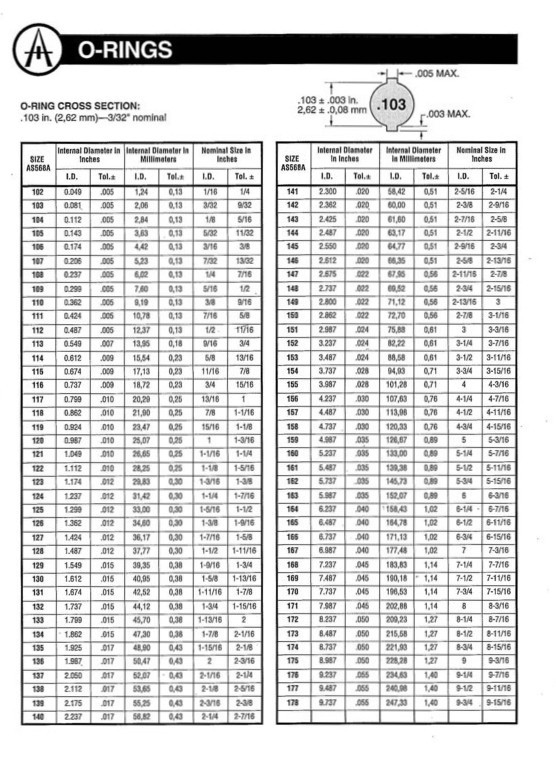

O-rings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. O-rings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the cross-section. During operation, the median pressure increases the deformation of the O-ring and so increases the sealing effectiveness. For best sealing effectiveness, the O-ring should have the largest possible cross-section. During installation the correct groove size, compaction, elongation/compression should be ensured. By static use the compaction should be 15 - 30% of the cross-section. By dynamic use it should be 10 - 18% (hydraulic), 4 - 12% (pneumatic). With regard to the ID, when installed the O-ring should be stretched max 6% compressed max 3% The material NBR has a high wear resistance and is resistant to mineral oil based lubricating oils and grease, hydraulic oils (H, H-L, H-LP), high-flashpoint pressure fluids (HFA, HFB, HFC), aliphatic hydrocarbons, silicon oil and grease, water up to ca. 80° C

Self-aligning pads with O-ring and exchangeable inserts

O Ring NBR - O Ring NBR - Oil Seal

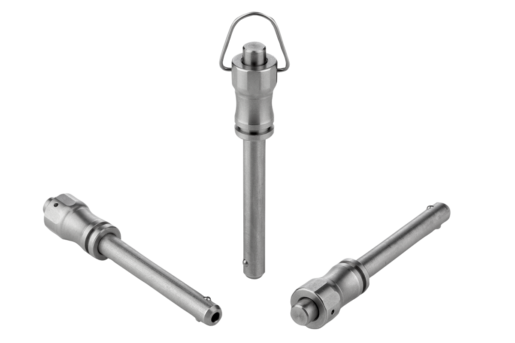

Ball lock pins with high shear strength

Datasheet 05020 Vertical, quick-acting clamps with - norelem

22430 Bevel gears in steel, ratio 1:1 toothing milled - norelem

ORING 045.00 X 02.50 FPM70

Cylindrical plain bearing - 23730 - norelem - Éléments standard

Bow shackles

O-rings APSOseal®

Joint torique NBR 106 x 3 - Shore 70, joint torique nbr

Self-aligning pads, adjustable, with O-ring, Form K, flattened POM

Joint torique NBR 106 x 3 - Shore 70, joint torique nbr

Yukon (YMS248) O-Ring for Ford 9 Differential, Differential

22400 Spur gears in steel, module 2 toothing milled - norelem

- 5 Simple Tips For Sustainable Living From Pamela Reif

- TC Fine Intimates Extra Firm Control Total Contour High-Waist Brief, Black, Small : : Clothing, Shoes & Accessories

- CinYana Boho Bedding Duvet Cover Sets 5 Piece Tufted Comforter Cover Set Shabby Chic Soft Breathable for All Seasons (King/California King, White) : Home & Kitchen

- Athleta Girl Sports Bra L 12 Gray Racerback Logo

- Wacoal 180363 Womens High-Impact Convertible Underwire Sports Bra Gray Size 36C

- Caged Lace Unlined Bra with Tie

- Carhartt WIP Landon Pant - Blue Stone Washed – Ninetimes Skateshop

- SIGMA 50: The Epic EDC Hoodie with Secret Pockets by Spindle

- 909 Cup Overflowing Stock Photos - Free & Royalty-Free Stock

- Wellness exercise, word cloud concept 6 Stock Illustration