The complete guide to PCB pad :types, size, spacing, repair and

By A Mystery Man Writer

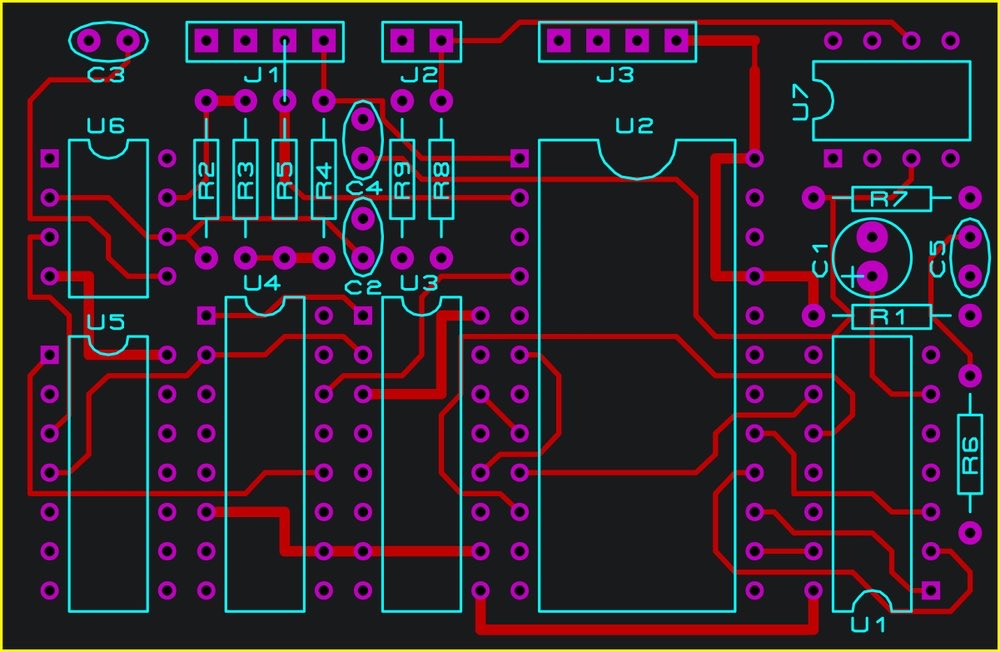

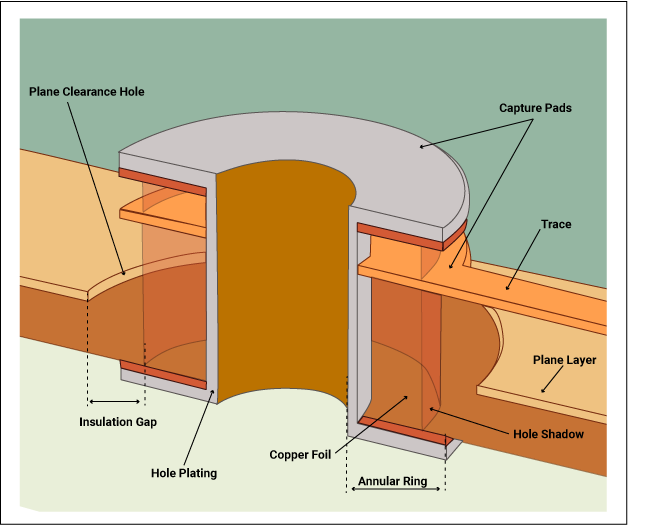

Soldering is one of the most important processes in PCBA processing. On printed circuit boards, electrical connections to all components are made via PCB pads. The PCB pads are a very critical part of the PCB that determines where components are soldered on the PCB.The size, shape, and position of pads in a PCB directly depend on the manufacturing quality of the board. Today we will take a look at the PCB pad in SMT soldering.

Soldering is one of the most important processes in PCBA processing. On printed circuit boards, electrical connections to all components are made via PCB pad.

BGA Design Guidelines - PCB Layout Recommendations for BGA packages

6-Layer PCB Stack-Up: A Comprehensive Guide to Design, Applications, and Manufacturing - MorePCB

Trace Spacing: A Guide For PCB Design - Jhdpcb

How to maintain and clean PCB stencils for consistent performance? - IBE Electronics

How to use PCB conformal coating ? ultimate guide for beginners - IBE Electronics

How To Repair Damaged /Missing PCB Pads INVISIBLE Fix, 45% OFF

PCB Layout and The requirements of The Drawing of Pads - PCB Design & Layout - PCBway

8 Types of PCB vias - A Complete Guide of PCB Vias

Solved Nep AutoZone Produces Brake Pads Using A Standard, 45% OFF

How to Repair Circuit Boards: A Step-by-Step Guide

PCB Layout: A Comprehensive Guide

What is a Pad in PCB Design and Development

- Ortho Traction Pads Premium Eruption Appliance

- X-PROTECTOR Non Slip Furniture Pads - Premium 16 pcs 2 Furniture Grippers! Best SelfAdhesive Rubber Feet Furniture Feet - Ideal Non Skid Furniture

- How to Replace Bike Brake Pads

- Pad Strips to Fix ripped pads and torn wire traces.

- Non Slip Furniture Pads - 8 Floor Protectors