Fiber movement during compression molding simulations with the ribbed

By A Mystery Man Writer

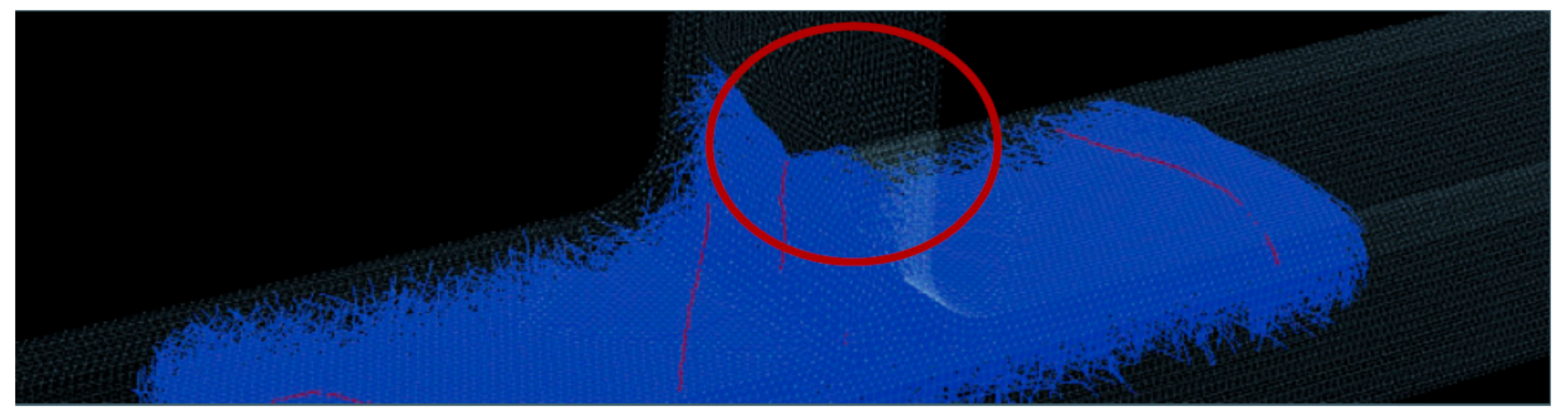

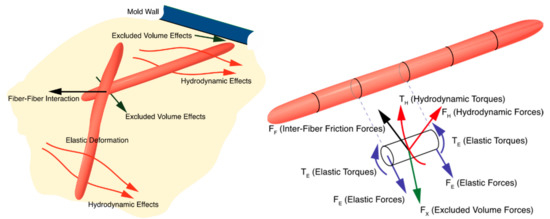

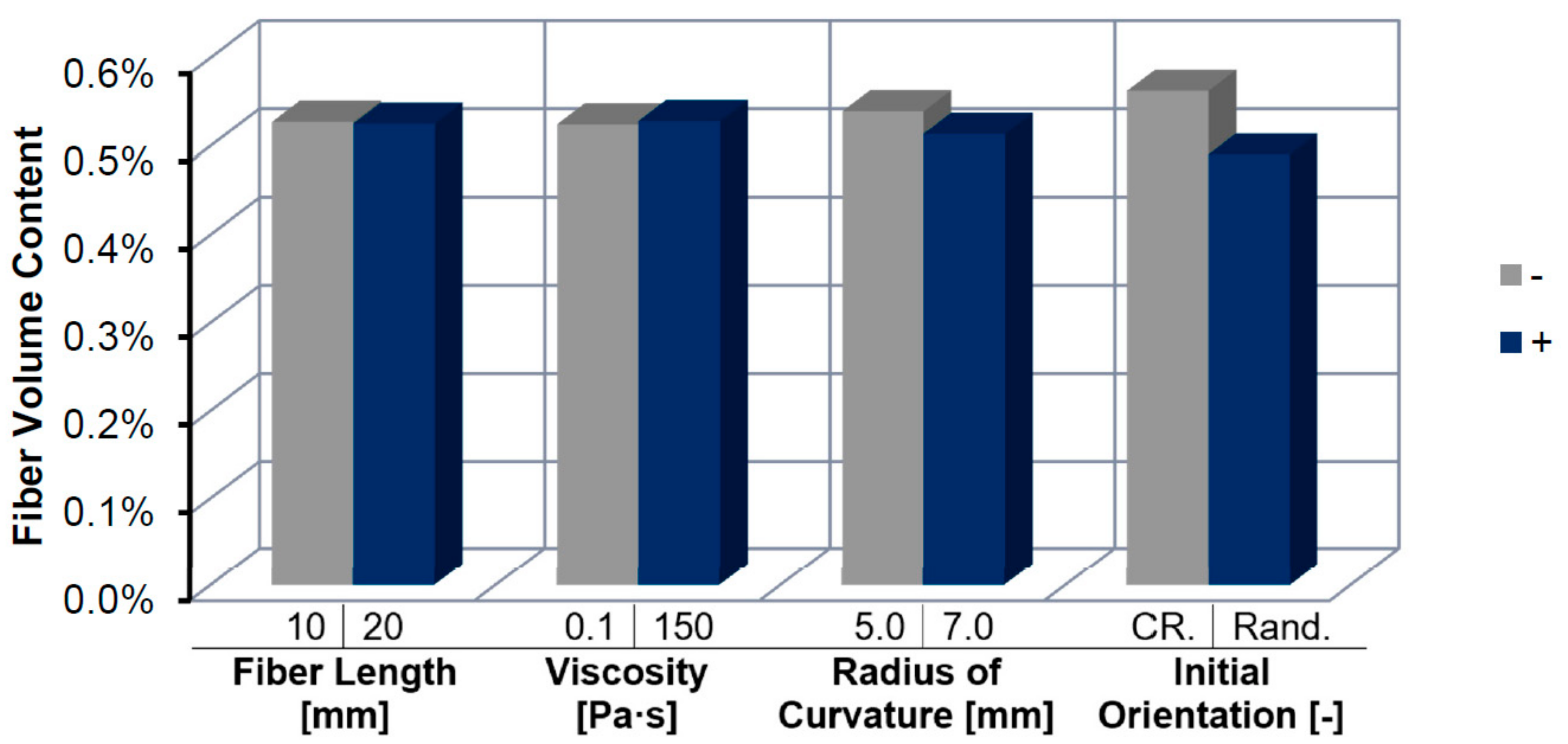

Download scientific diagram | Fiber movement during compression molding simulations with the ribbed plate at consecutive time steps 1-4. from publication: Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation | Compression molding of long fiber reinforced composites offers specific advantages in automotive applications due to the high strength to weight ratio, the comparably low tooling costs and short cycle times. However, the manufacturing process of long fiber composite parts | Fiber, Compression Molding and Reinforcement (Psychology) | ResearchGate, the professional network for scientists.

A Commercial tire tread pattern of PCR 205/55R16.

PDF) Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

PDF) Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

A Commercial tire tread pattern of PCR 205/55R16.

The spectrum characteristic of sound source for 7 mm lateral groove.

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

PDF) Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation

J. Compos. Sci., Free Full-Text

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

J. Compos. Sci., Free Full-Text

J. Compos. Sci., Free Full-Text

Increased boundary conditions shown in red. Note: Fiber radius is shown